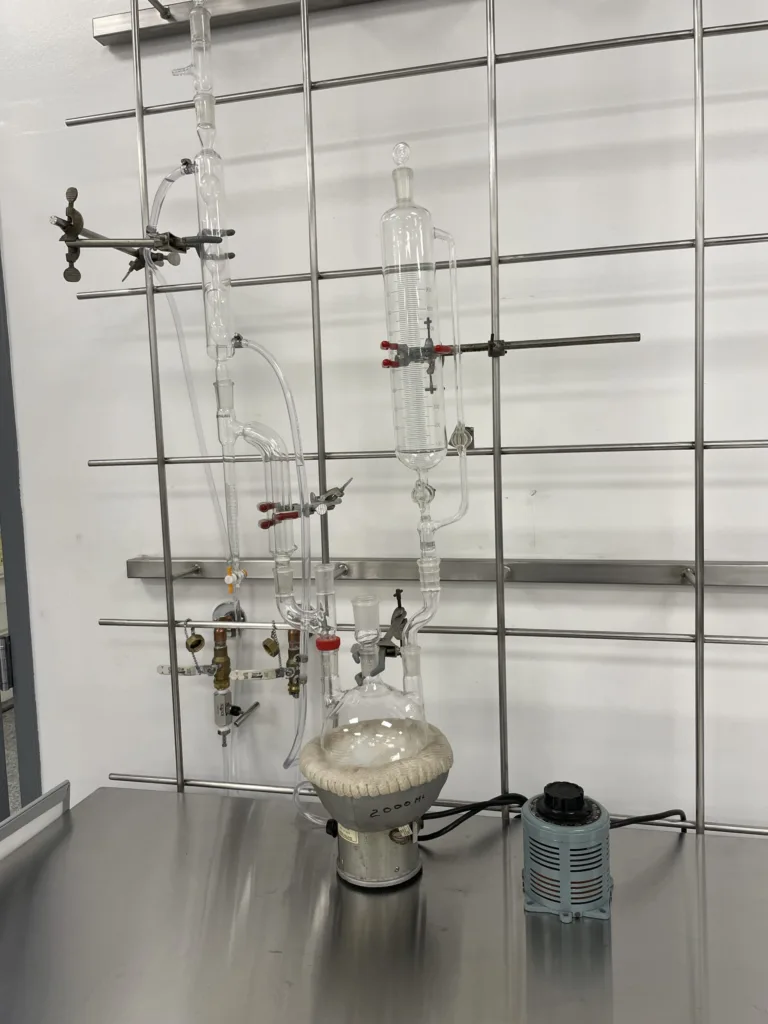

Evaporation Equipment

Design systems customized to client and facility needs for evaporators used in an array of industries.

Custom Evaporation Solutions

RCM Thermal Kinetics offers a wide range of evaporator styles that are utilized in many industries. With a focus on energy conservation, we take your specifications and design a system customized to the needs of the facility.

thermal kinetics

Evaporation Equipment & Technology

Evaporation technology is used in any process that requires concentration of a stream by removal of water or other solvent. The process of evaporation is energy-intensive; any evaporator system design approach needs to take great consideration into the heat recovery philosophy and overall utility usage of the final system design. Product characteristics also need to be considered in the system design; many product characteristics can be altered in an evaporation process, especially in Food and Beverage applications.

Evaporator Industries & Applications

Our team at RCM Thermal Kinetics have experience delivering systems across multiple industries. Learn more about Evaporators and their applications, types and designs below as our engineers share their knowledge and expertise.

- Chemical Production

- Food and Beverage

- Pharmaceutical Production

- Agricultural Chemical Production

- Pulp and Paper

- Oil and Gas

- Fuel Ethanol

- Chemical Plant Waste Systems

- Removal of Solvents from Oils

- Cannabinoid Oil Refining

- Pharmaceutical Product Recovery from Waste Streams

- Gelatin Production

- Concentration of Sugar Solutions

- Sodium Hydroxide (NaOH) Production

- Sulfuric Acid Production

- Phosphoric Acid Production

- Brewery Waste Concentration Systems

- Chemical Recovery in Metal Plating processes

Types of Evaporators

There are several varieties of evaporator designs commonly used throughout different industry sectors. The selection of the appropriate design is based on many factors that consider the efficiency of the system and the appropriate use of a specific evaporator type to maintain final required product characteristics. Within the framework of the system design is the selection of the appropriate equipment within the design. The main piece of equipment used at the heart of the evaporation process is the evaporative heat exchanger. The varied system designs can utilize different technologies within the evaporator system. The two main technologies used in an evaporator design by RCM Thermal Kinetics include:

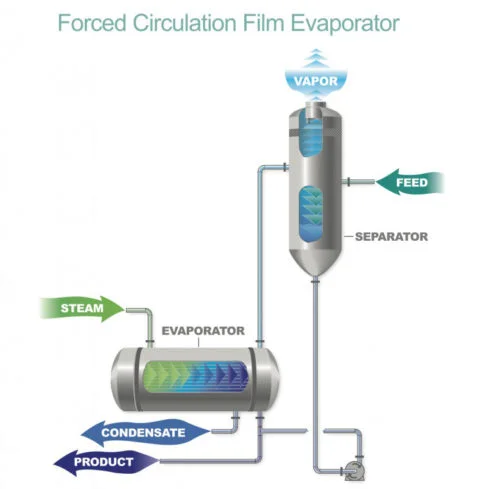

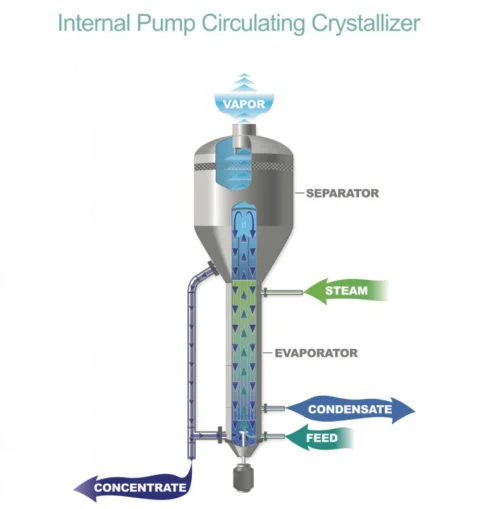

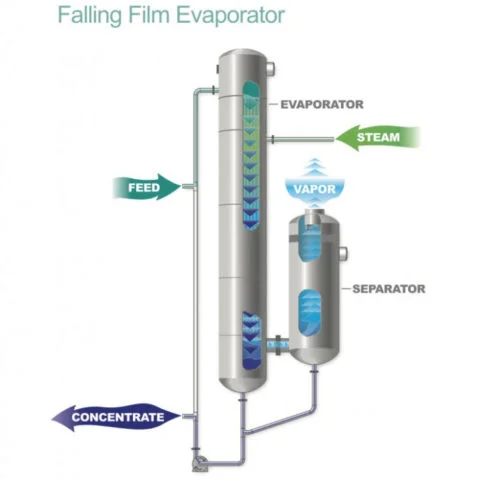

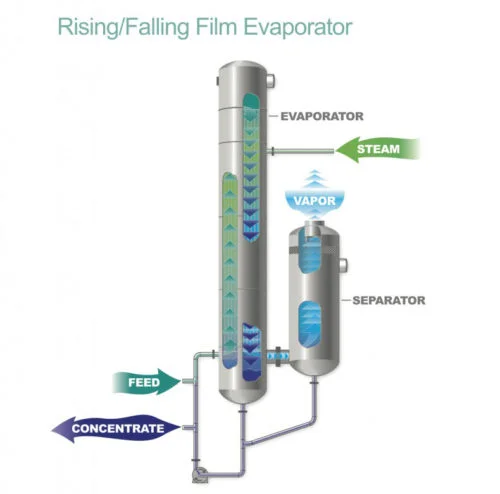

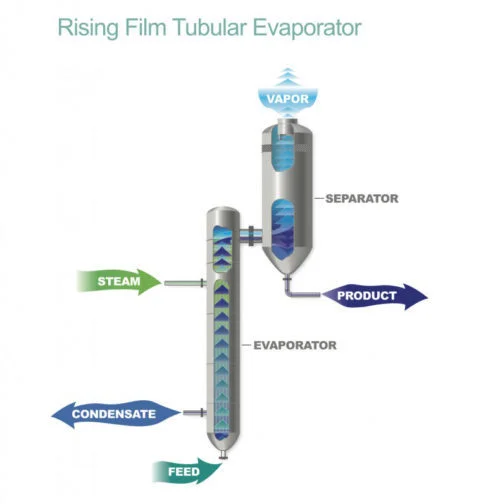

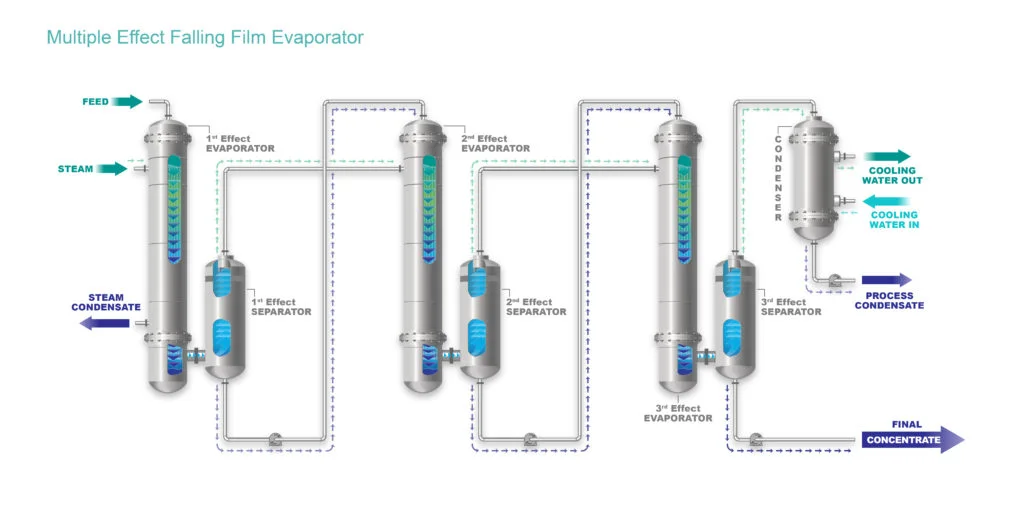

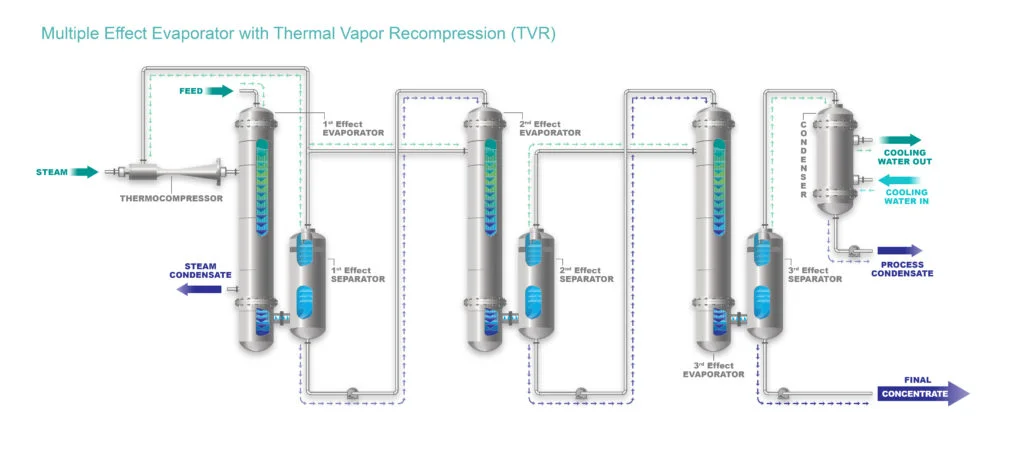

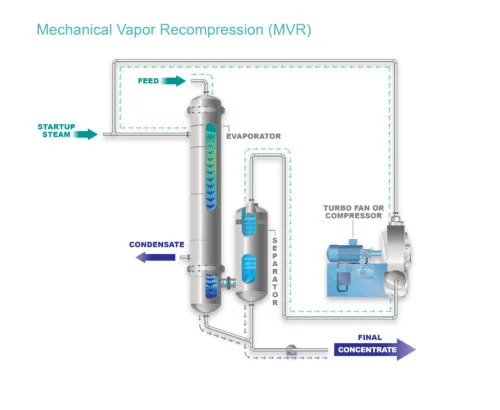

A shell and tube heat exchanger is used to drive the evaporation process. The specific detailed design of the shell and tube results in a variety of evaporator system configurations that include:

- Falling Film Evaporator

- Rising Falling Film Evaporator

- Flash Evaporator

- Forced Circulation Evaporator

As the name suggests, a plate evaporator uses a plate heat exchanger in the system design to drive the evaporation process. It offers several benefits over a tubular design.

- The plate heat exchanger is relatively easy to disassemble, inspect, and clean.

- Depending on the process fluids, a higher heat transfer coefficient is achieved.

- The compact heat exchanger area reduces the overall system size and headroom requirement

- Lower installation cost

Selecting the Right Evaporator

With so many factors to analyze, it may seem very daunting to select a suitable evaporator for your specific industry and application. RCM Thermal Kinetics is here to help you navigate the evaporator selection process from start to finish. We provide a wide-ranging selection of evaporators, industrial distillation equipment, and industrial scrubbing equipment.

If you’d like to learn more about the products and services we offer, reach out to us today to request a quote.

Evaporator System Design

Our goal remains to offer the best process solutions that contribute to our clients’ success, add value to their operations, and protect our community and environment.

Christopher J Brown, Founder of Thermal Kinetics

Let’s Collaborate on Scientific Success

Learn more about our customer product and process development activities in our Testing Laboratory.