Engineering Services

Trusted extensions of client engineering teams bringing experience and innovation to maximize output.

The RCM Process & Industrial group in Buffalo, NY is an innovative and solutions-focused team providing full service multi-discipline engineering, procurement, construction management services using modern design tools.

Multidisciplinary Engineering

Our team has extensive knowledge with Natural Gas, Hydrogen, Nitrogen, Oxygen, Steam, and other Gas Systems. We have worked with over 25 global hydrogen plants and have optimized modular construction, skidded systems, and “stick-built” designs for schedule, cost and O&M excellence with safety and quality at the forefront of all decisions.

- Clients look to RCM’s Process & Industrial group for expertise in oil and gas, commodity and specialty chemicals, polymers, petrochemicals, and food processing markets.

- Our experienced team is large enough to have the breadth and depth of technical competence, modern suite of design and engineering tools, and dynamic enough to be close to our clients to meet project goals in a responsive way.

- From facility layouts and plant design & upgrades to laser scanning and 3D modeling, RCM works closely with your team to understand the unique requirements of your project.

Process & Industrial

Electrical & Instrumentation

RCM Engineering’s Process & Industrial team has a deep understanding of new plant and upgrade design and engineering requirements. Utilizing the latest in design tools, the team has expertise in:

- Arc Flash

- SKM, ETAP

- SEL settings and programming

- Electrical drawings, specifications, and manuals

- Grounding and lightning protection

- P&IDs

- Control system design

Engineering, Procurement, Construction & Management (EPCM)

RCM Engineering will partner with you to support your project needs and help you determine the best contracting strategy for your unique requirements. Our team uses the latest design tools and technology and includes early construction involvement in the process to ensure minimal downtime for project installation.

Process & Industrial

EPCM

The EPCM approach to projects offers the owner the ability to execute projects within budget and on schedule minimizing construction delays due to lagging information, material or equipment. We track progress and maintain contingency plans to stay on schedule and document project progress.

Our approach – safety, quality, innovation and technology – enables our team to minimize risk, tightly manage scope, schedule and cost, and deliver full turn-key solutions allowing your team to focus on your core business.

Bringing experience & innovation to enhance your output

RCM Process & Industrial is a premier technology solutions company that has been providing lifecycle Engineering and Aftermarket services to Industrial Gas, Chemical, and Food Processing clients for over 20 years.

process & Industrial

Mechanical & Piping

RCM Engineering’s Process & Industrial team has a deep understanding of new plant and upgrade design and engineering requirements. Utilizing the latest in design tools, the team has expertise in:

- Equipment and Process Plant Layout Development

- 3D Piping Design Using the Latest Plant Design CAD Systems

- Modular & Skidded Process Systems to minimize field construction

- Piping Isometric Drawings

- Pipe Size and Wall Thickness Calculations

- Piping Stress Analysis –Caesar II, AutoPIPE

- Piping Network Flow / Pressure Analysis, Pump Sizing Calculations

- Pipe Support Design

- System and Equipment Reliability Studies

- Equipment Specification, Selection and Purchasing

- Steam Utility Distribution Systems

- Plant O&M – Pumps, chillers, heat exchangers, cooling towers, boilers

- Relief device analysis, sizing, and validation – safety and controls

- Process and Instrumentation Drawings (P&ID)

- ASME Code Calculations and Design (ASME B31.1, B31.3, ASME Section 8)

Process & Industrial

Civil & Structural

The RCM Engineering team has an extensive background and civil and structural work for new and renovation building design for commercial, manufacturing, industrial plants, substations, offices, and garages. Our expertise includes:

- Civil/Site Improvements

- Foundations/Drainage

- Condition Assessmentst

- Seismic & Structural Analysis

- Site Studies

- Permitting

- Life/Safety

PROCESS & INDUSTRIAL

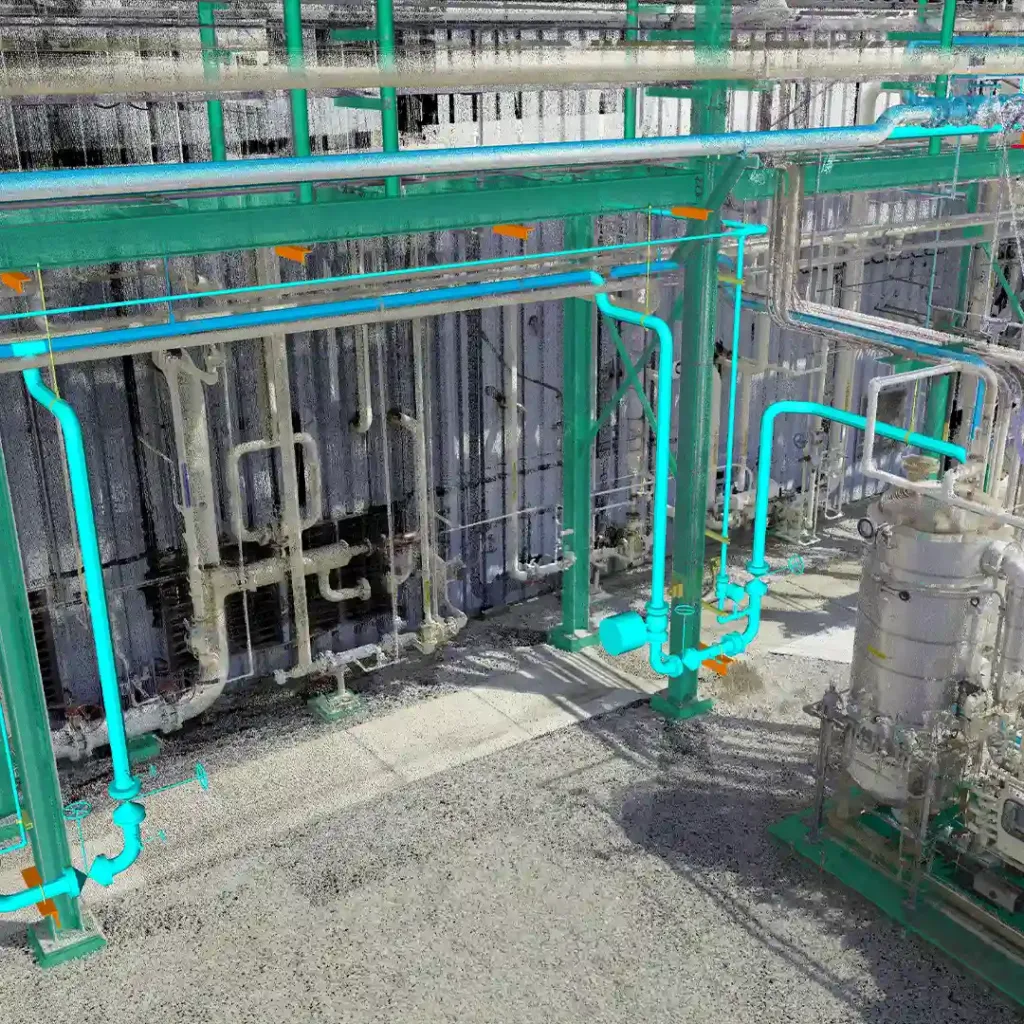

Laser Scanning & Project Technologies

Our team offers information management solutions and Integrated Design Engineering to recreate any existing facility into an accurate digital design. Using Building Information Management (BIM) technologies we can design new upgrades and plants with fully integrated engineering, procurement, and construction requirements. The approach facilitates collaboration between the engineering team, the owner and the construction team to develop a design that meets the owner’s requirements and can be constructed within budget and schedule.

After construction drawings are generated, the 3D model is brought to construction as a 4D tool. 4D is simply time attached to 3D elements that are used for creating visual 4D schedules where objects on screen appear or disappear during timeline simulation with color codes that show areas that are ahead or behind schedule. Our innovative approach to design and construction includes:

- Laser scanning existing facilities to develop a 3D model and design in real environment,

- Reverse engineering

- 3D modelling and bill of materials reporting

- 4D integrated schedule for construction

- Electrical drawings, specifications and manuals

- Ground Penetrating Radar (GPR)

- Animated procedures and safety videos

Process & Industrial

Process & Chemical

The RCM Thermal Kinetics team specializes in process and chemical engineering, applying advanced principles to design, optimize, and enhance industrial processes. Our expertise ensures improved efficiency, safety, environmental compliance, and cost-effectiveness across various industries, offering these key services:

- Process design, simulation and modeling

- Feasibility studies and techno-economic analysis

- Laboratory testing

- Process optimization

- Scale-up and pilot plant services

- Chemical safety and hazard analysis

- Environmental compliance and sustainability

- Project management

- Troubleshooting and process improvements

Key Benefits

Our process and chemical engineering services help industries design and optimize safe, efficient, and compliant systems, driving productivity and sustainability.

- Sustainable Solutions: Reduce waste, energy use, and environmental impact.

- Enhanced Efficiency: Boost productivity, cut costs, and optimize resources.

- Improved Safety: Identify and mitigate potential hazards.

- Regulatory Compliance: Meet environmental, safety, and industry standards.

Problem solvers with decades of Engineering Excellence

Meet our reliable Engineers and see how our approach to projects can benefit your next upgrade or new project.