Pharmaceutical Production

Our engineers support pharmaceutical plants by providing unique process solutions that economize production operations.

Our Competitive Advantage

We specialize in solvent recovery systems that allow chemical recycling back to production and custom designed evaporation systems that recover high value product.

Pharmaceutical Production

Solvent Recovery

Waste streams from pharmaceutical production plants contain high value organic chemicals that can be recovered and reused in the upstream process. This methodology is referred to as Solvent Recovery. These applications more than any other, require a distillation pilot testing campaign to validate design, operation set points, utilities and the resulting recovery efficiency.

Pharmaceutical Production

Steam Stripping

Another major concern at the back-end of the pharmaceutical production process is the reduction of waste materials and the maintenance of discharge streams from process wastewater to meet EPA guidelines for organic compounds. Component discharge limits ranging from 100 ppb – 10 ppm are common and dependent on the solvent in question. RCM Thermal Kinetics designs custom Steam Stripping systems to achieve acceptable EPA legal limits for organic components.

Pharmaceutical Production

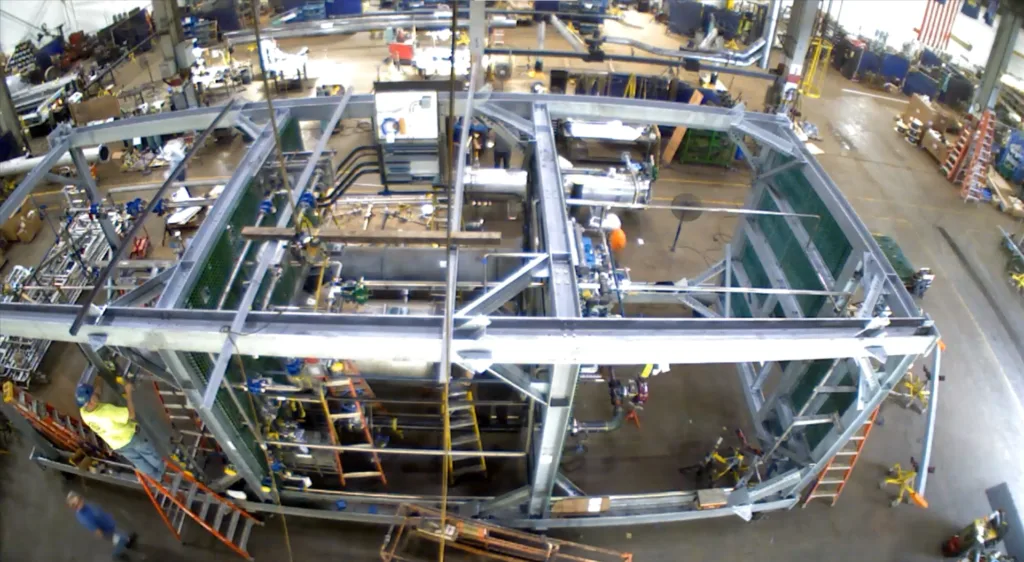

Modular System Design

Modular systems are fully assembled in the shop, which simplifies the site installation process. The overall project cost and duration are minimized. The module contains all vessels, heat exchangers, valves, and instrumentation require for the process. All equipment is mounted in the steel framework and piped together within the boundary limits of the module. Electrical control wiring is run to a skid-mounted junction box for integration into the plant control system.

Pharmaceutical Production

RCM Thermal Kinetics Testing Capability

Modern computer simulation methods fall short when trying to predict distillation behavior for multi-component organic feed streams. These type of waste streams from pharmaceutical facilities require pilot testing to develop empirical process data and process guarantees. Thermal Kinetics lab is fully equipped to test and de-risk these types of projects.

Why RCM Thermal Kinetics

- Customized Specialty Chemical Process Solutions

- Energy-Efficient Designs and Integration

- Pilot Testing Capability | De-Risking Project

- Single-Source Project Coordination

- Process Systems Integration for Maximum Financial Return

Maximize your success

Contact us today or request a quote for more information.